How Quasicrystals Are Revolutionizing 3D-Printed Metals

In the world of materials science, a recent breakthrough has shed light on the unusual strength of 3D-printed metals: quasicrystals. This discovery could pave the way for more durable aerospace components and other industrial applications, changing how we engineer metallic structures.

Andrew Iams’ Remarkable Discovery

Andrew Iams, a materials research engineer at the National Institute of Standards and Technology (NIST), stumbled upon something remarkable while examining an aluminum alloy at an atomic scale. Upon closer inspection, he discovered that the atoms formed an unusual pattern associated with quasicrystals. This discovery was not only exciting for its rarity but also for its implications for metal strength. According to Technology Networks, these quasicrystals were strengthening the alloy in ways traditional crystal structures could not achieve.

What Sets Quasicrystals Apart?

The unique nature of quasicrystals lies in their atomic arrangement. Unlike traditional crystals with repeating patterns, quasicrystals can fill space without repeating, existing beyond the 230 known repeating patterns. This defied traditional crystallography rules and was initially met with skepticism when first discovered by Dan Shechtman in the 1980s. Shechtman’s persistence eventually led to a Nobel Prize, as his findings revolutionized perceptions of material properties, setting the stage for Iams’ contemporary advancements.

The Role of 3D Printing

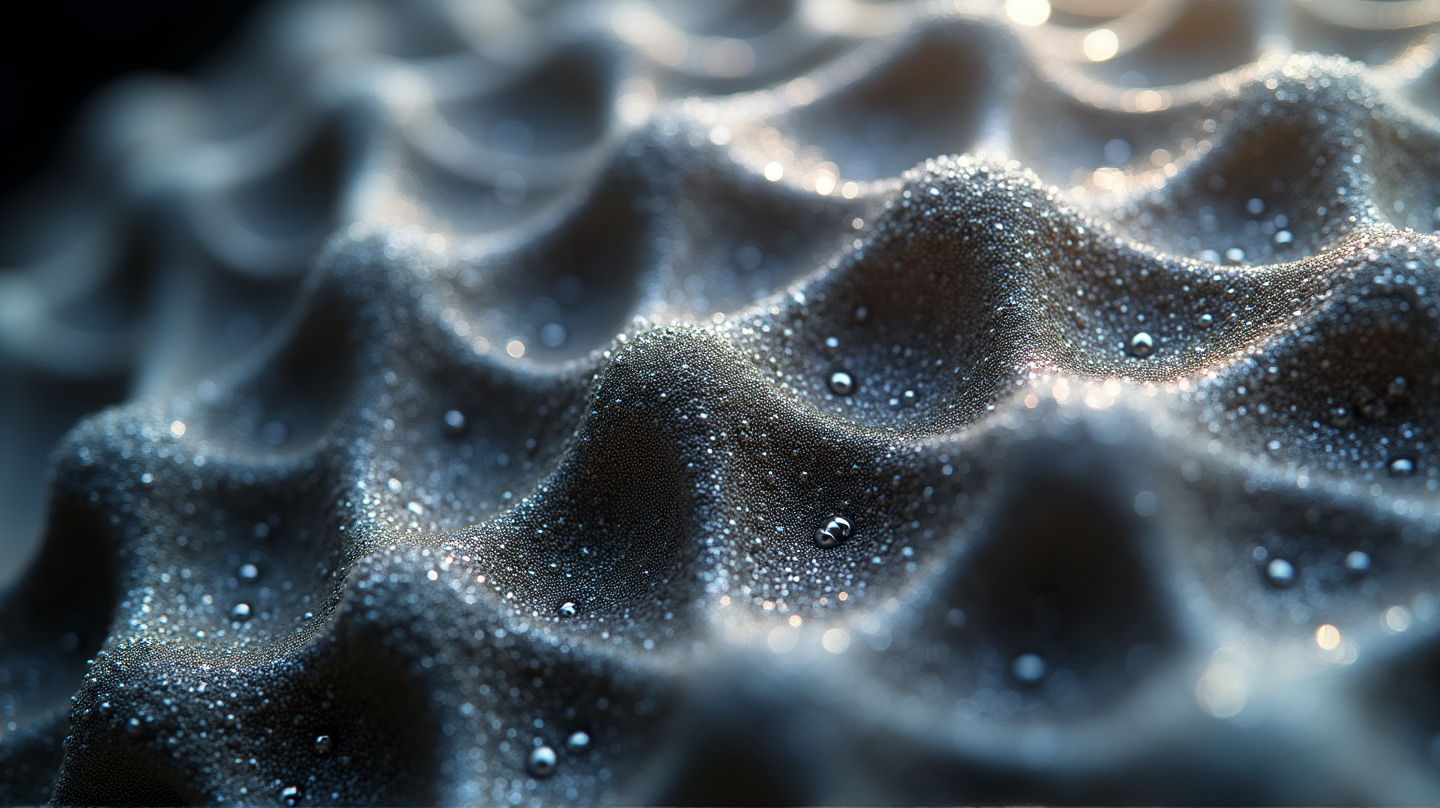

One of the many advantages of metal 3D printing is its ability to create complex shapes impossible by traditional means. A notable example is the fuel nozzles designed by GE for airplane engines, which transitioned from a cumbersome 20-part assembly to a singular, lightweight design. This process, known as powder bed fusion, layers and fuses metal powder using a laser, ideal for complex geometries.

However, 3D printing with metals like aluminum poses challenges, as the process can lead to undesirable cracks. Yet, a breakthrough discovered by a team in California involving zirconium additives provided a solution, enhancing the strength and integrity of aluminum alloys.

Implications of Quasicrystals in Metal Strengthening

Quasicrystals disrupt the regular atomic patterns in metals, inherently introducing defects that contribute to increased material strength. The discovery of fivefold rotational symmetry in these structures—an indication of quasicrystalline properties—was pivotal in understanding their role in reinforcing aluminum.

The Future of Alloy Design

The revelation of quasicrystal capabilities in strengthening metals holds potential for future alloy design. As stated by NIST’s Fan Zhang, understanding these properties on an atomic scale will be crucial for the adoption of these new materials in critical components like military aircraft parts. The research opens up new possibilities for designing alloys intentionally incorporating quasicrystals, potentially revolutionizing how we approach material science in various industries.

With these findings, the landscape of material strength for 3D-printed metals is changing, offering new horizons in durability and applications across industries.